Management

Systems and plants must be managed in such a way that the investment can be durable throughout its life cycle, profitable and safe. The asset integrity approach meets all these requirements as it ensures that the corporate assets are safeguarded in the short, medium and long term.

Managing the project

Operate and maintain the asset for its entire life until decommissioning.

Maintenance engineering

CMMS population and optimisation

Inspection engineering and welding management

Spare parts managements

Audit and assessment

Root Cause Analysis and troubleshooting

Design for maintenance

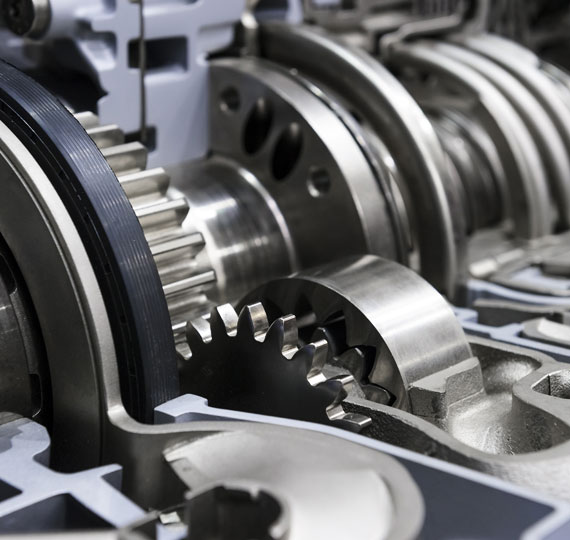

Maintenance Engineering

Maintenance engineering is based on consolidated tools, such as Reliability Centered Maintenance and FMECA and Reliability Maintenability Availability Safety which allow the development of maintenance plans and procedures to be loaded into the Computerized Maintenance Management System (SAP, MAXIMO, INFOR) and ways of optimizing new orders and under stock levels at the basis of spare parts interchangeability (SPIR) complete the picture.

Once the maintenance has been planned, it must be monitored with the managerial, economic and technical KPIs and controlled through the normalization of bad actors and the development of Root Cause Analysis and troubleshooting activities.

Inspection Engineering

The Asset integrity provides for the development of Risk-Based Inspections for the preparation of asset inspection plans and the implementation of Integrity Operating Windows (IOW) to define the critical parameters and the corresponding tolerated operating ranges without incurring damage and defect consequences of integrity.

The context of structural integrity and consequently the inspections, as for the maintenance plans, provides for all those in-depth and detailed services, such as the definition of the baseline and the drafting of technical specifications related to the NDTs execution methods.

Operational Maintenance

Maintenance must first recognize assets that may generate failures that pose threats to safety and the environment (SECE) and assets which malfunction compromises system performance (OCE); once SECE and OCE have been defined through bow-tie analysis, the assets must be managed in terms of planning and scheduling of controls and reviews, implementing an optimal mix between the various maintenance policies (preventive, corrective and improvement), based on risk.

Shutdown and Turnaround

The planned shutdowns of the systems must be prepared, planned and executed in detail because both human and economic resources are at stake; in this case, thanks to its Shutdown Manager Pansoinco is able to identify the criticalities of shutdowns and turnarounds, guaranteeing compliance with the shutdown budget, the quality of the interventions and the stop and restart times.

Assessment and technical assistance

Pansoinco uses a consolidated auditing system for operations and maintenance and in this context it can provide technical specifications for extraordinary maintenance and revamping, as well as technical due diligence. Alongside process audits, Pansoinco develops specific training plans and provides specialist technical assistance, such as fitness for service or the implementation of changes to information systems.